Ubuchwepheshe be-extrusion obubandayo bomkhono webha yensimbi

Izici zobuchwepheshe obubandayo be-extrusion bomkhono webha yensimbi

(1) Ubuchwepheshe bokwakha bokuxhuma okubandayo kwe-extrusion yomkhono wensimbi yensimbi kulula futhi kulula ukuyiqonda.

(2) Ubuchwepheshe bokuxhuma umkhono wensimbi obandayo bungonga isikhathi esiningi ekwakhiweni uma kuqhathaniswa nendlela yendabuko yokushisela.

(3) Uma kuqhathaniswa nokwakhiwa kokuxhumeka kwensimbi yensimbi yendabuko, ubuchwepheshe bokuxhuma okubandayo bomkhono webha yensimbi bunganciphisa izindleko zephrojekthi.

(4) Ubuchwepheshe boxhumano lwe-cold extrusion lomkhono wensimbi yensimbi bufaneleka ekuxhumekeni kwe-radial extrusion yensimbi eyizimbambo enobubanzi φ16-φ40 esakhiweni sikakhonkolo esiqinisiwe.

Izidingo zobuchwepheshe ze-extrusion ebandayo yomkhono webha yensimbi

Ubuchwepheshe obufanelekile be-extrusion kanye nezinga elifanele lokwamukelwa kufanele kwamukelwe ekwakhiweni koxhumano lwe-ribbed steel bar extrusion ukuze kuqinisekiswe ukuthi ikhwalithi yokwakha ihlangabezana ngokugcwele nezidingo zokuklama.

Izinto kanye nemishini yokuxhuma okubandayo kwe-extrusion yomkhono webha yensimbi

(1) Izinto ezibonakalayo

1, insimbi

Ibha yensimbi ekhishiwe kufanele ibe nesitifiketi sekhwalithi, futhi ukuma kwayo kwendawo, ubukhulu kanye nezakhiwo zemishini kufanele zihlangabezane nezidingo zamazinga kazwelonke.I-Rebar kufanele ihlolwe ngaphambi kokusetshenziswa futhi amasampula athathwe ukuze ahlolwe izakhiwo zemishini.Ukuhlaziywa kokwakheka kwamakhemikhali kufanele futhi kwenziwe lapho ukuphuka kwe-brittle kanye nezakhiwo zemishini zokuqinisa ngokusobala zingavamile.Uma i-rebar igcinwa futhi ithuthwa, uphawu olungaphezulu akumele lonakale, futhi luzopakishwa ngobunono ngokwenqwaba ukugwema ukugqwala nokungcoliswa.

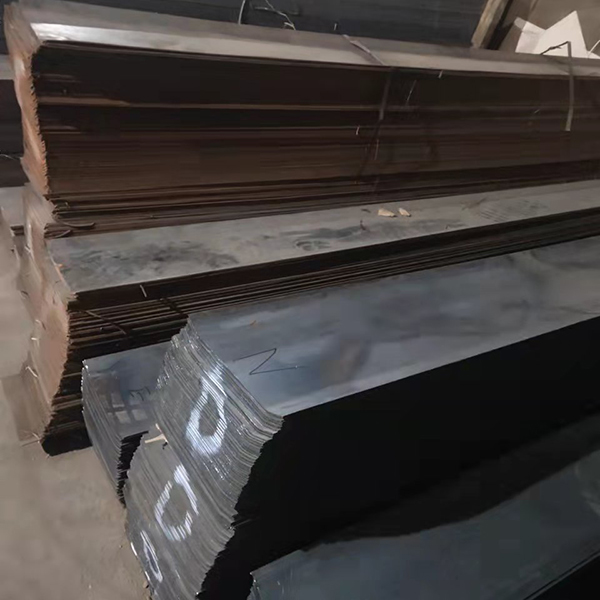

2, umkhono

I-sleeve material yenziwe nge-seamless steel tube efanelekayo kwi-calendering.Izakhiwo ezilinganisiwe zemishini, usayizi womkhono nokuchezuka kuhlangabezana nezidingo.Imikhono kufanele ivikelwe ekugqwaleni nasekungcolisweni ngesikhathi sokugcinwa nokuthuthwa, futhi izobhekwa futhi yamukelwe ngamaqoqo ngesikhathi sokwamukelwa.Imikhono kufanele inqwabelane ngokuya ngemininingwane ehlukene ngesikhathi sokugcinwa, kanti imikhono izoba nesitifiketi sekhwalithi yefekthri.

(2) Izisetshenziswa

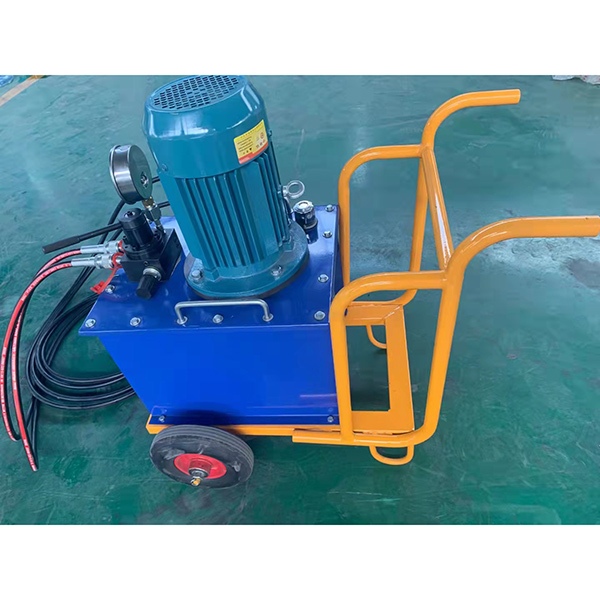

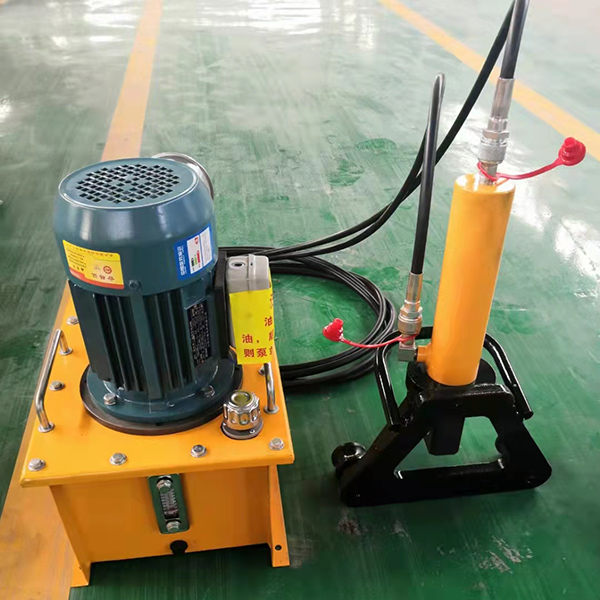

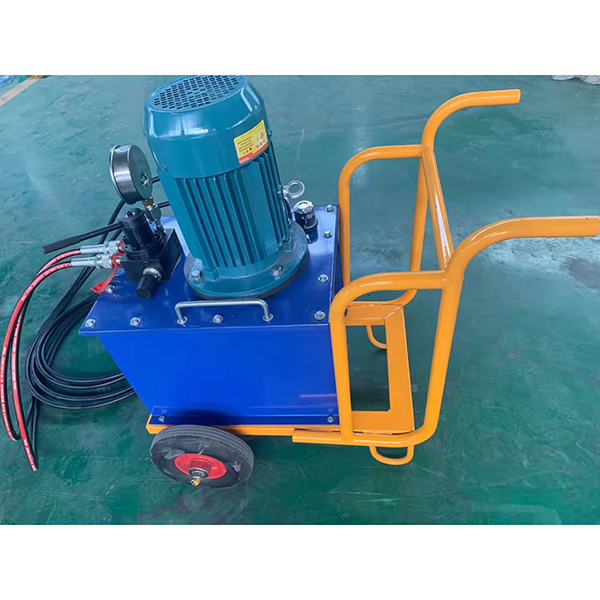

1, imishini extrusion

Imishini yokuxhuma i-Extrusion yenziwe nge-crimper, iphampu kawoyela enengcindezi ephezulu kanye nepayipi likawoyela elinomfutho ophezulu kakhulu.Iphampu kawoyela enengcindezi ephezulu ingumthombo wamandla we-extrusion, ingcindezi yokusebenza elinganiselwe ingu-80Mpa;Idivayisi ye-Crimping yizingxenye eziphezulu ze-extrusion yensimbi, kunezinhlobo ezimbili, ingcindezi yokusebenza ephezulu ye-100Mpa;I-Yjh-32 ifaneleka ukugoqa izinsimbi zensimbi ze-φ16-φ32, i-yJH-40T ifaneleka ukugoqa izinsimbi zensimbi ze-φ32-φ40.Cindezela u-die, umkhono, ibha yensimbi kufanele isetshenziswe ndawonye, kunezincazelo eziyisishiyagalolunye zomshini wokunyathelisa, inombolo ephawulwe ku-dayisi imele ububanzi bebha yensimbi, kufanele ihlolwe uma usebenzisa.

Umshini wokuxhuma umkhono wensimbi obandayo we-extrusion uhlanganisa nemishini yokusiza ye-extrusion kanye nemishini ekhethekile ye-extrusion.Imishini yokusiza ye-Extrusion: i-spreader, i-angular grinder, njll;Imishini ekhethekile ye-Extrusion ihlanganisa: ikhadi lokumaka, ibhodi lekhadi lesayizi.

Okwesithathu, ukwakhiwa koxhumano olubandayo lwe-extrusion ye-reinforced avenue tube

Inqubo yokusebenza yokwakha uxhumano lwe-extrusion ebandayo

1. Hlola ukuthi ingabe okokusebenza kwe-extrusion kusebenza ngokujwayelekile ngaphambi kokusebenza koxhumano olubandayo lwe-extrusion yensimbi yensimbi, futhi ulinganise ingcindezi yokukhipha ukuze uhlangabezane nezidingo ngaphambi kokusebenza.

2. Umkhono wensimbi kanye nesikhunta kukhethwa ngokuvumelana nencazelo yokuxhuma ibha yensimbi.Amamodeli esikhunta wokuxhuma izinsimbi zensimbi ezinobubanzi obufanayo kanye namamodeli esikhunta wokuxhuma izinsimbi zensimbi ezinobubanzi obuncishisiwe kufanele ahambisane nezinhlinzeko ezifanele ku-JGJ107 ne-JGJ108 ngokulandelanayo.

3. Khipha ukugqwala, isihlabathi, uwoyela nezinye izinhlobo ezingxenyeni ezixhunyiwe zensimbi yensimbi.

4. Hlola ibha yensimbi nomkhono wensimbi.Uma isiphetho sebha yensimbi sinezicathulo zehhashi ezibucayi, ezigobile noma usayizi wezimbambo ezinde kakhulu, kufanele zilungiswe kusenesikhathi noma zipholishwe ngesondo lokugaya, kodwa kwenqatshelwe ukupholisha ubambo oluphambanayo lwebha yensimbi nokusika ingxenye enkulu ngokushisela ugesi.

5, ngerula elijule kubha yensimbi yokuphela kophawu lokumisa, uphawu lokumisa lushuthekwa kubude bomkhono wensimbi, hlola ibanga lomaka ukusuka kuphawu lokuma elingu-15mm, ukuze uhlole ukuthi ibha yensimbi ifakiwe yini endaweni ngemuva kokuklwebha.

6. Faka ibha yensimbi emkhonweni wensimbi ngokophawu lokuma.Ukuphela kwebha yensimbi akufanele ibe ngaphezu kuka-5mm ukusuka maphakathi nobude bomkhono.

7, ngokwezinhlinzeko zezikhathi zokucindezela nokuhlehlisa kokucindezela.

Isibonisi somkhiqizo