Umkhiqizi womkhono onesihloko esibandayo

Izici zenqubo yokuqopha enesihloko esibandayo

1. Isihloko esibandayo senziwa ekamelweni lokushisa.Isihloko esibandayo singathuthukisa izakhiwo zemishini yezingxenye zensimbi.

2. Inqubo yokubumba izihloko ezibandayo ingakhuphula izinga lenzalo yezinto ezibonakalayo.Kuyindlela yomshini wokucindezela esekelwe ekwenziweni kwepulasitiki, engakwazi ukusika kancane noma ukungasikwa.Izinga elijwayelekile lokusebenzisa izinto liku-85% ngaphezulu, eliphakeme kakhulu lingafinyelela ku-99% ngaphezulu.

3. Ingathuthukisa ukusebenza kahle kokukhiqiza.Isikhathi nenqubo yokuguqulwa komkhiqizo wensimbi kufushane, ikakhulukazi ezingxenyeni zokucubungula umshini wokwenza iziteshi eziningi, kungathuthukisa kakhulu ukukhiqiza.

4. Ubuchwepheshe bokubumba okubandayo bungathuthukisa ubulukhuni bemikhiqizo futhi buqinisekise ukunemba kwemikhiqizo.

Izidingo zenqubo yokubumba isihloko esibandayo ezintweni ezingavuthiwe

1. Ukwakheka kwamakhemikhali kanye nezakhiwo zemishini zezinto ezingavuthiwe kufanele zihlangabezane nezindinganiso ezifanele.

2. Izinto ezisetshenziswayo kufanele spheroidized ukwelashwa annealing, isakhiwo metallographic of the material kuyinto eyindilinga pearlite level 4-6.

3. Ubunzima bezinto zokusetshenziswa, ukuze kuncishiswe ukuthambekela kokuqhekeka kwezinto ngangokunokwenzeka futhi kuthuthukiswe impilo yesevisi yesikhunta, izinto ezibandayo ezibandayo ziyadingeka ukuze zibe nobunzima obuphansi ngangokunokwenzeka ukuze kuthuthukiswe ipulasitiki.Ukuqina kwezinto ezingavuthiwe ngokuvamile kuyadingeka ukuze kube ku-HB110~170 (HRB62-88).

4. Ukunemba kwezinto zokudweba ezibandayo kufanele kunqunywe ngokuvumelana nezidingo ezithile zomkhiqizo kanye nenqubo.Ngokuvamile, ukunemba kwe

5. Izinga elingaphezulu lezinto ezibandayo zokudweba lidinga ukuthi ifilimu yokugcoba ingabi mnyama, futhi indawo engaphezulu akufanele ibe nemihuzuko, ukugoqa, imifantu, izinwele, ukugqwala, isikhumba se-oxide kanye nemigodi yemigodi nokunye ukukhubazeka.

6. Ubukhulu obuphelele bongqimba lwe-decarburization ohlangothini lwerediyasi yezinto zokudweba ezibandayo akufanele budlule u-1-1.5% wobubanzi bempahla eluhlaza (isimo esithile sincike ezidingweni zomkhiqizi ngamunye).

7. Ukuze kuqinisekiswe ikhwalithi yokusika yokubunjwa okubandayo, izinto zokudweba ezibandayo ziyadingeka ukuze zibe nendawo eqinile kanye nesimo somgogodla othambile.8. Ukuhlolwa kwe-Cold-top Forging kufanele kwenzelwe izinto ezidonswa ngokubanda, futhi ukuzwela kwezinto zokwakha ukuqina okubandayo kufanele kube kuncane ngangokunokwenzeka, ukuze kuncishiswe ukwanda kokumelana nokuguquguquka ngenxa yokuqina okubandayo ngesikhathi. ukuguquguquka.

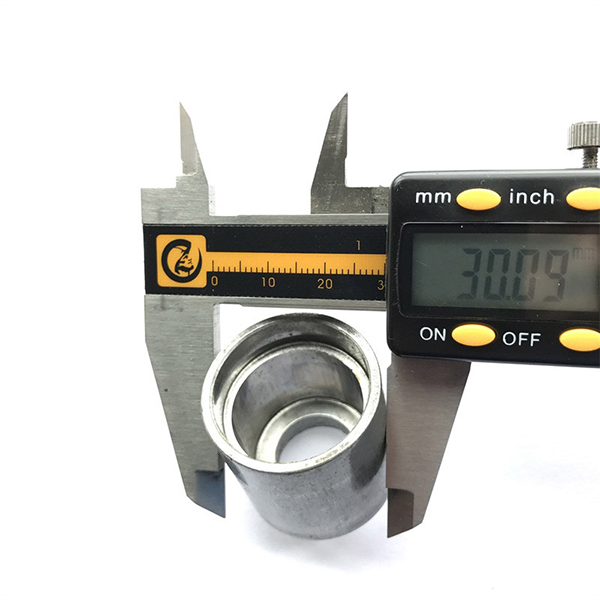

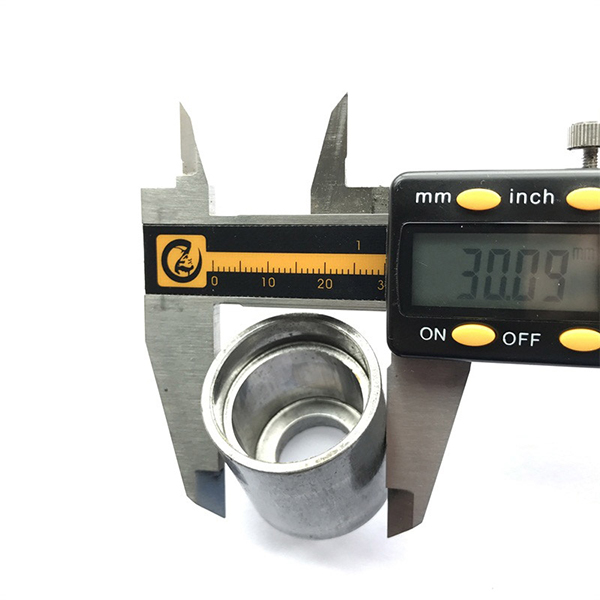

Isibonisi somkhiqizo