Umkhono Wekhwalithi ephezulu Obandayo we-extrusion

Izici Eziyinhloko

Ukuzinza kwayo akuthintwa ukwakheka kwamakhemikhali emigoqo yensimbi, izici zomuntu, isimo sezulu, ugesi nezinye izici eziningi.Ukuvikelwa kwemvelo okuluhlaza, akukho ukungcola, kuhlangabezana nezidingo zokuvikelwa kwemvelo, akukho ukusebenza komlilo ovulekile nokwakhiwa okuphephile futhi okuthembekile.Isebenza kuhlelo olubanzi lwezinhlelo zokusebenza, ezifanele zonke izinhlobo zokuma futhi okufanayo, ukunciphisa ukuxhumeka kwebha yensimbi.Ikhwalithi ezinzile futhi enokwethenjelwa, kulula ukuyisebenzisa, ukusebenza okulula, isivinini sokwakha esisheshayo.

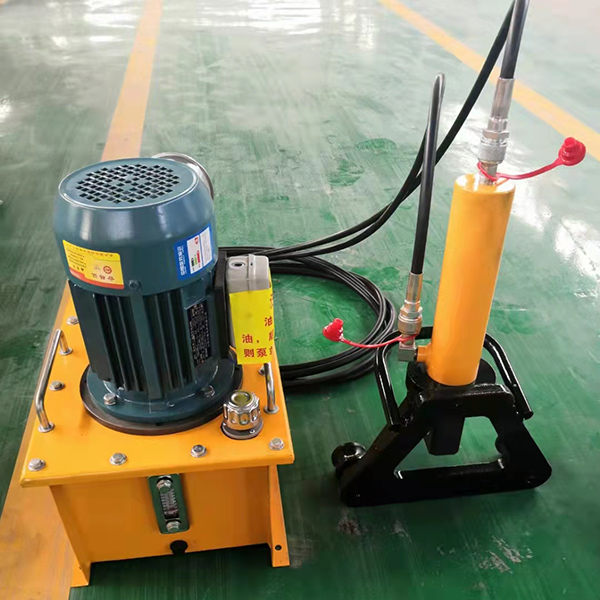

Inqubo yokusebenza komkhono wokuxhuma we-extrusion ebandayo iyethulwa

1. abasebenzi abasebenza ngokungaguquki, futhi baphumelele ukuhlolwa, ngesitifiketi.

2. Ukuze kuthuthukiswe ukusebenza kahle, endaweni yokucubungula, umkhono wensimbi uxhunywe nensimbi yensimbi ukuze ugcwalise ingxenye yekhanda le-extrusion, kanti enye ingxenye yekhanda le-extrusion ikhishwa kusayithi, kodwa umkhiqizo ophelile. kufanele kumiswe futhi kubekwe ukuvimbela ukungcola ku-cylinder extrusion.

3. Emsebenzini we-extrusion, kunconywa ukuthi uqale kusukela ku-indentation mark phakathi nendawo kuya kokubili kokuphela.

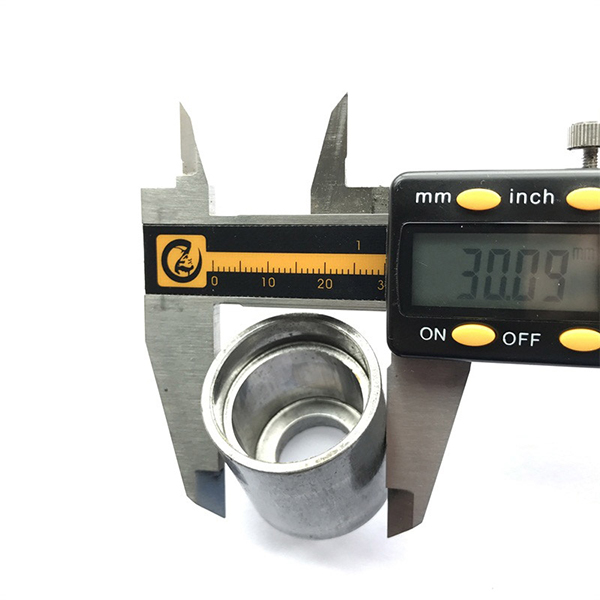

I-4, umkhono wokuxhuma we-extrusion obandayo kufanele uhlangabezane nokucaciswa kwebha yensimbi, ngesizukulwane esikhulu sendlela encane akuyona yonke into efiselekayo, kuye ngokuthi isimo, isibonelo: lapho ububanzi bebha yensimbi bushintsha, uma ibha yensimbi ihluka ngebanga. , ingashintshwa ububanzi obukhulu, uma ibha yensimbi ihluke ngebanga elingaphezu kwelilodwa, isigaba soguquko kufanele sengezwe.

I-5, ngaphambi komsebenzi wokuxhuma kwe-extrusion, kufanele iphawule kahle ekugcineni kwe-bar (isikhundla, uphawu lokuhlola), amamaki okubeka inhloso yawo eyinhloko ukumaka ukuqiniswa kwensimbi kanye nesikhundla somkhono, ngoba ukunwetshwa komkhono wensimbi emva kokukhishwa, ukubeka amamaki ku- joint, ngakho umaki wokuhlola, angabheka kalula indawo yomkhono wensimbi ukuthi ilungile.

Isibonisi somkhiqizo